Laminate… it’s made of paper!

Laminate… it’s made of paper!

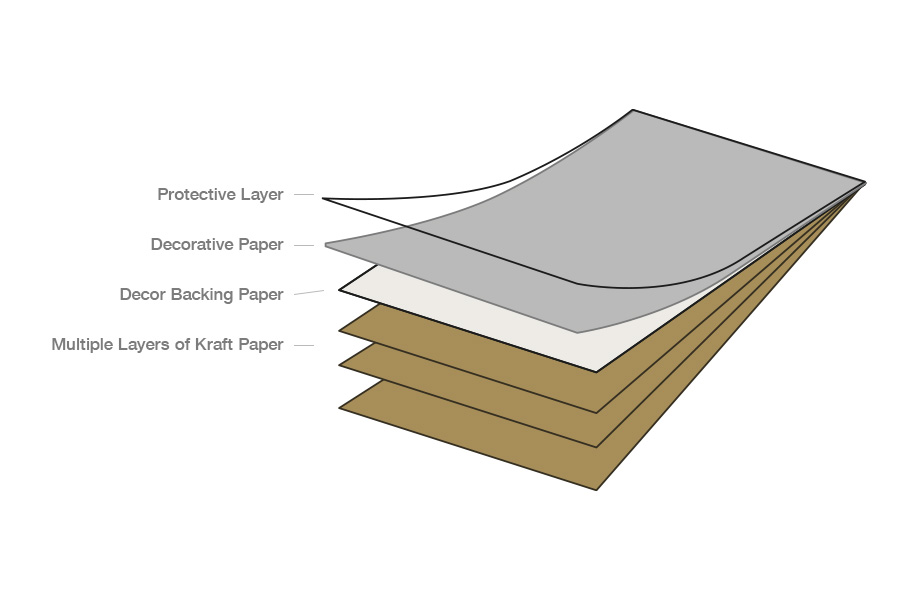

One ongoing misconception is that laminate is made of plastic. However, the primary material used to create our decorative laminates is naturally occurring sustainably sourced paper.

To make our renowned Formica® Laminate, kraft paper, which forms the core of the material is impregnated with resin and pressed together at high pressure and temperature with a resin impregnated “décor” paper, which not only gives it the colour and surface aesthetic but gives it a high resistance to wear, impact, heat and staining.

This makes the completely sealed, hardwearing and hygienic surface we all recognise.

A quick and easy guide to the laminate production process

Whether you are using Formica Laminate for a kitchen or for bigger projects such as hospitals, schools, hotels, offices or restaurants, the manufacturing process remains the same.

-

Stage one: paper impregnation

First, the kraft paper which makes up the finished product’s base is fed on a roll through a machine that impregnates it with phenolic resin. This gives it the strength and rigidity it needs. Once it’s dried, it’s stored ready for use later in the production process.

Meanwhile, the surface paper and top paper are impregnated with melamine resin to generate the laminate’s decorative finish and durability.

-

Stage two: pressing

Using a large press, the treated papers are assembled into packs and layered between steel plates. Then they’re heated to 150°C and compressed under a pressure of 0.5-0.75 tons per square inch for just over an hour. Once they’re removed and cooled, they’re cut to size and checked for quality control.

Learn more about our wide range of products for commercial interiors and order your free samples online today.